On any 2T engine that is tuned for higher performance the power band will be raised into a tighter (peak) RPM area mostly due to the addition of an expansion chamber style performance pipe and the cylinders port timings. The DiTech isn't much different but the RPM isn't raised as high as a non-direct injected engine because the stock port timings and even the 70cc kit port timings are pretty tame. The DiTech was intended to be an ultra clean fuel efficient two stroke and the stock bower band is very broad but the restricted power output is only 3.8HP, 4.4HP derestricted.

Most performance parts available for the Piaggio based SR50 DiTech are carryovers from the carbureted days of the Piaggio and were never intended for the DiTech. There's nothing wrong with that as long as you don't use information gathered from a non-DiTech Piaggio setup to tune your DiTech.

To get the best performance from a constant velocity transmission (CVT) based two stroke scooter such as the SR50 DiTech, the optimum RPM band must be maintained throughout the entire transition of the variator as seen in this video.

To govern that RPM from start to finish with as little RPM variation as possible a combination of variator roller weight, clutch spring tension and contrast spring tension must be chosen. Each of these serve a separate purpose but 2 of them, roller weight and contrast spring tension must have a balance.

Clutch spring tension

The clutch spring tension will determine when (what RPM) the clutch shoes start to come in contact with the clutch bell, until then the engine will spin up freely and with little effort. Where the lower power band begins (RPM) is where the shoes should start to engage the clutch bell. From idle to that RPM you want the engine to rev effortlessly so by the time you start to move the engine is already at an RPM where it begins making it's best power.

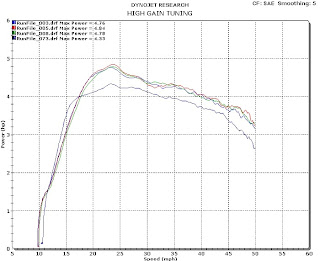

In the Dyno graph below comparing a 70cc DiTech engine to a 86cc Race engine the blue and red circles show where the lower power band begins. The blue and red ovals show where the power band peaks. Despite your riding preference, you should not let your clutch engage below the circled rpm or you will experience poor take offs and possibly never get the engine into its peak power band.

With the power band known you can better choose where you want the clutch to engage. The two extremes would be comfortable street use on one end and drag racing on the other.

A comfortable street use engagement would be at the bottom of the power band. That will allow the engine to make good power and have a smooth take off but you will feel and hear it get stronger as the rpm's get higher toward the peak. An example of that on the DiTech engine would be where the circle begins or slightly after (6500 rpm) but not before.

A drag racing setup should engage just below the peak rpm so most of the power is already made but not so high that the clutch slips. It's all or nothing when drag racing so a good engagement rpm on the race engine graph would be 10,5000.

Roller Weights

As the engine rotates, the roller weights create the centrifugal force necessary to push the front variator pulley halves together. In their relaxed position (idle) they allow the pulley halves to relax and let the drive belt fall to its lowest range position needed for starting out.

The faster the engine rotates, the more force that will be created to push the pulley halves together and the drive belt higher up the pulley to its highest range needed for cruising.

Contrast Spring

At the rear of the transmission is the fixed pulley half, movable pulley half, contrast spring and clutch. The job of the contrast spring is to push the movable pulley half together so that the drive belt is forced to its highest position of the fixed pulley, this puts the transmission in its lowest range. Since the drive belt doesn’t stretch, that pulls the belt down into the lowest part of the variator.

If the rollers weights are responsible for pushing the drive belt one way and the contrast spring tension is responsible for pushing it the other, a balance in pressure must be maintained so the pulley halves not only transition easily and at the correct time but that the drive belt stays tight. This balance is pretty good when the scooter is stock but few of us tend to keep it that way.

Keeping it balanced

An imbalance starts as soon changes are made to the two stroke engine to make it more powerful. Since this is a CVT scooter and we cannot choose its RPM shift points manually so that it stays in the power band, we have to adjust the transmission to do it for us and do it properly.

Something as simple as changing the pipe isn't so simple on a CVT 2 stroke scooter. For an expansion chamber pipe to perform at its peak, it has to operate within a specific pulse frequency and temperature. If the temperature needs to be at a specific temperature, the manufacturer will instruct you where that should be and ways to help get it there.

For the pipes available to us the design is so that we can usually leave our engines running at their factory desired temp. This doesn't mean that part number XYZ performance pipe is going to operate the same on every engine at every location. For any performance pipe that we can add it has been tested to perform best at its fully warmed up temperature. If your going to putt around the neighborhood and never get your exhaust blistering hot, do not add a performance pipe then complain about your performance or lack of.

Some pipe manufacturers like LeoVince will include components such as stiffer clutch springs and lighter rollers to help re-balance the transmission so the owner has a better experience. Others just hope you know what the hell your doing, or don't really care.

Are you grasping this?

Now if you have been paying attention, you know why they included stiffer clutch springs and lighter roller weights. Your new pipe has a power band that is higher than your stock pipe but also starts at a higher rpm. Therefore the stiffer clutch springs will hold off the clutch engagement until the rpm's have reached the point where the pipe is making good power and won't get bogged down before it gets a chance to work.

The lighter rollers are necessary to keep the centrifugal force (balance) the same at your new (higher) operating rpm. If you fail to install the lighter rollers the force the heavier rollers create at the higher rpm will start to compress the contrast spring too quickly causing your transmission to up-shift prematurely.